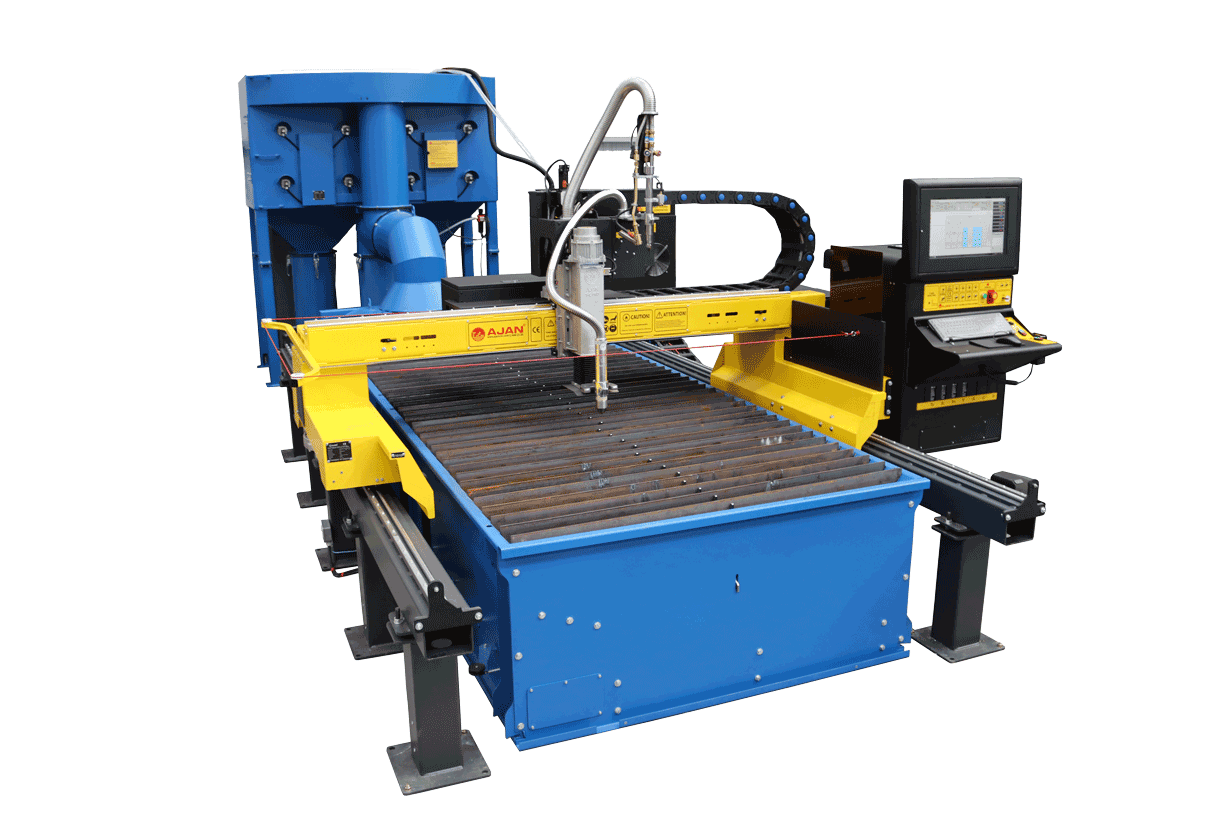

Plasma cutter machines are a number of the greatest time-savers that metallic shops may buy. A CNC plasma cutter may slice by means of metallic approximately 5 opportunities faster than lanterns, and also its CNC capacity enables consumers to plug any sort of master plan into the cutter’s pc and reduced the concept into or away from the slab of metallic being made use of. These machines permit reduces to be repeated all day long with no loss of rate, resulting in huge improvements to performance as well as creation speed. Any sort of store may locate worth in these advantages, yet the tip of buying this equipment still may not seem like a sure thing without comprehending just exactly how this tools operates. Below is actually an additional explanation of exactly how these equipments provide their benefits.

Plasma cutting has been actually around for many years and is valued for its own convenience in making clean cuts to slab metal. This modern technology involves making use of gas that is actually electrically kindled and heated up to plasma, which is actually each liquefied and also gasoline, at approximately 45,000 levels Fahrenheit. The lantern’s nozzle concentrates the plasma and drives it at the slab metal, which can be up to two ins thick. Incredibly, the plasma arc, which is less than 1/16 in wide, is thus highly effective that it impacts the liquified metal out the opposite of the sheet it is actually cutting. The location encompassing the arc is actually defended through passive fuels, which are actually also made use of to provide the reducing fuel to the faucet.

The driver of one of these cutter machines may effortlessly change any blueprint or make with the usage of computer-aided concept program and also after that configure the maker to cut the precise style into steel continuously. Artists that produce multiple copies of original steel sculptures can additionally gain from making use of CNC plasma cutters best plasma cutters.

Since plasma cutters may produce such astonishingly scorching temperatures, operators who would like to stay away from the probability of serious injury need to constantly review documents and don welding-appropriate garments just before using some of these makers. Plasma light beams may also destroy eyes that are actually left behind vulnerable, therefore anyone in the vicinity of an energetic plasma cutter must continuously put on welding shatterproof glass along with shadow 5 lenses.